Best Fully Automatic Fly Ash Bricks Machine

- Home

- Products

- Fly Ash Bricks Machine

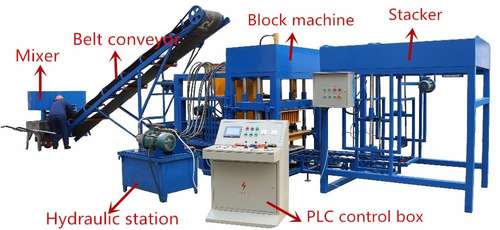

stationary chassis made of angles, channels, and sheet metal by M.S. equipped with hydraulic jacks to compress a 150 MT hydraulic power pack with a 10 HP three-phase motor, a sweep, an oil cooling system, and a plate vibrating system, as well as hardened moulds to release 10 bricks, 2 blocks, and 6 zigzag and I-shaped pavers in a single motion with dimensions of 230*100*75MM or any brick size, and a 400*200*200MM block. 20 second cycles produce a minimum of 13500–14500 bricks, 2500–2800 blocks, and 7500–8500 zigzag or I-shaped pavers each 8-hour shift. Other according to your needs kind Size Available)

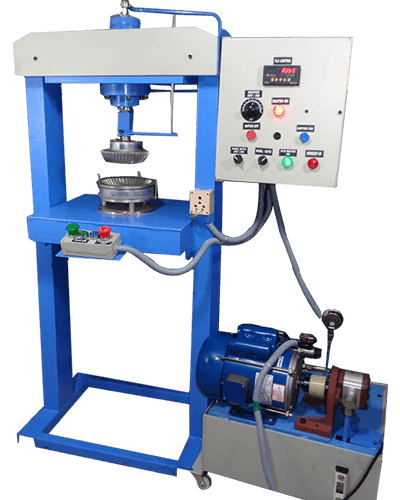

This Machine has been designed with the latest Open Cam Technology and have the capacity to produce 110 pieces of Cups per minute. The size range varies from 35 to 450 ml.

- Gear Transmission System and PLC Screen

- Centralized Rotating System

- Automatic Lubrication with Oil Bath

- Photoelectric Sensors and PLC Screen

Fully Automatic Fly Ash Brick Making Machine Specification

| FEATURE | SPECIFICATION |

| PRESSURE CAPACITY : – | 150 MT |

| ELECTRIC MOTOR : | 10HP (CROMPTON / ABB or Shreeji Motor) |

| VIBRATION MOTOR :- | 2 HP (Shreeji) |

| PALLET FEEDING :- | Automatic |

| General Power | 4.5 KW |

| TYPE OF CONTROL :- | Automatic With PLC Panel & Sensor |

| OIL TANK :- | 450 to 500 ltr. Approx (68 no hydraulic oil) mm |

| PER STROKE PRODU. :- | 10pcs Bricks (230*100*75MM), 2pcs Block (400*200*200MM) & 6Pcs Zigzag & I shape Paver (Other as per Type & Size) |

| CYCLE PERIOD :- | 18 to 20 second |

| PRODU. CAPACITY : – | 13500 to 14500 Bricks & 2500 to 2800pcs block 7500 to 8500pcs Zigzag & I shape Paver per Shift (8 Hours) Other as per type & Size |

| colour Fidder System :- | Yes |

After Sale Service

- A user guide is including to assist with the machine installation and adjustment and help solve problems that may be encountered.

- Technicians are available to guide the installation & adjustment on site.

- Free training is available and ongoing until the operator fully understands the operation and maintenance of our machine. The buyer should cover travelling and accommodation expenses of our technicians.

Related product from Priti Enterprises

Paper Plate Making Machine

Paper Cup Making Machine

Rice Mill / Huller Machine